Most of the time, different solutions are required to be offered for different processes in heat transfer applications.

After obtaining the necessary information regarding the process, it is designed by mechanical engineers specialized in the field and schematic drawing is then produced. During controls made over schematic drawing, shop drawings are produced after confirmation that no dimensional problem is in question is received.

Each heat exchanger whose shop drawings are confirmed is only special to the process they are designed for and is generally unique. After heat exchangers are manufactured, they can be isolated as well if required and heat loss can be minimized this way.

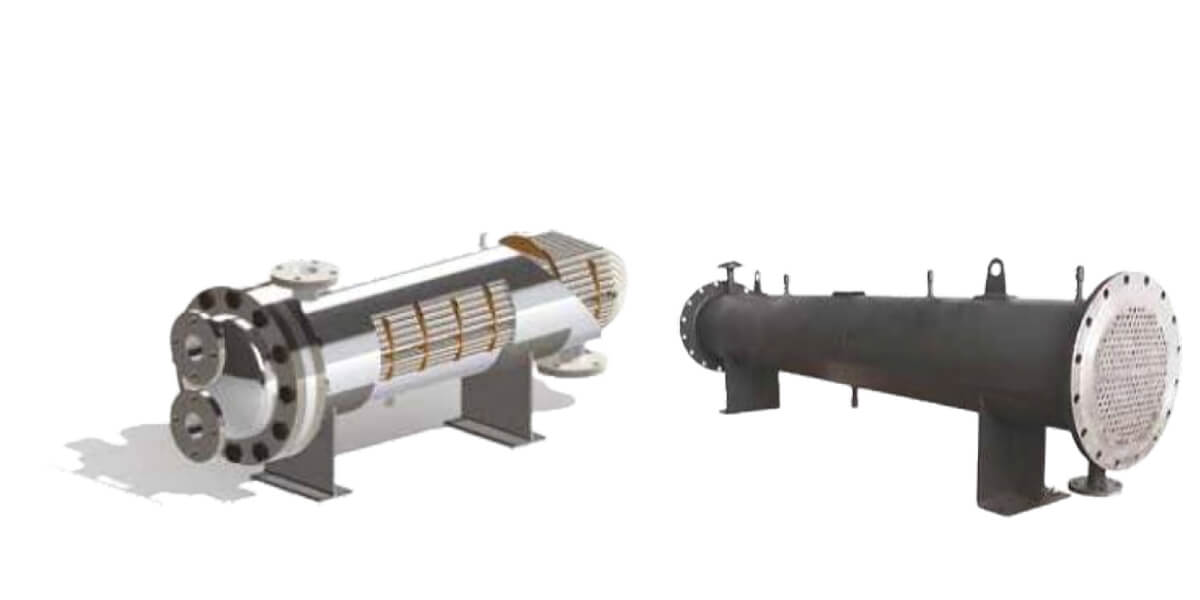

There is no capacity limit in the manufacture of tube exchangers. Exchangers can be grouped in more than one way by series or parallel connection and their capacities can be increased. Fete Vessel, who is a supplier to plants requiring great capacities such as petrochemical plants or power plants, is one of the leading companies in the sector with its broad experience.

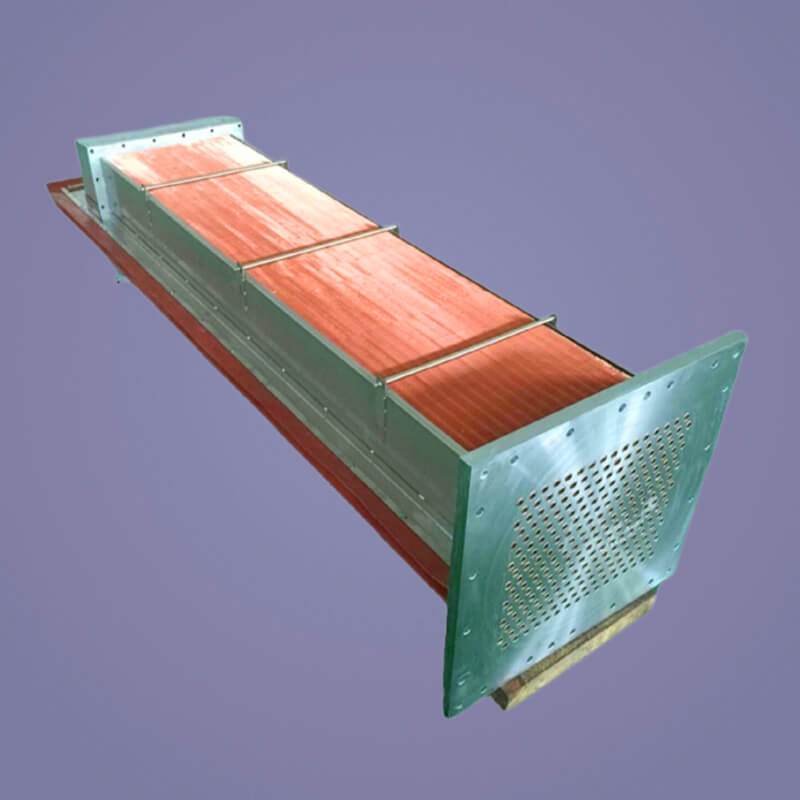

Depending on their process requirements, the following materials can be used in tube exchanger- ST37

- ST35.8

- AISI304

- AISI316

- Copper

- Titanium

- Bafon