In numerous industrial operations, the utilization of compressed air is indispensable. However, a common issue arises with industrial air compressors—they generate substantial heat, posing a threat to sensitive components within the process.

To counteract the adverse effects of air compression, operators often turn to aftercoolers and intercoolers. This article aims to shed light on the disparities between these two cooling devices.

Distinguishing Intercoolers from Aftercoolers

For those new to the field, discerning between various heat exchangers might present a challenge. While aftercoolers and intercoolers are frequently mentioned interchangeably, they exhibit nuanced discrepancies in their design and function. Let's delve into the specifics of how an intercooler differs from an aftercooler.

Understanding Intercoolers

An intercooler serves as a heat exchanger designed to dissipate heat from the air produced by an air compressor. A proficient intercooler can effectively restore the temperature of compressed air to levels approximating the surrounding environment.

How Intercoolers Operate

Typically employed in turbocharged engines, intercoolers play a vital role in cooling compressed air before it enters the engine's circulation. By acting as an intake air cooling unit, intercoolers enhance engine performance by augmenting air density, thus bolstering overall efficiency and power output.

Exploring Aftercoolers

In contrast, an aftercooler functions as a mechanical cooling unit predicated on the principles of heat exchange between two mediums, typically water and air. Aftercooler units are adept at achieving temperatures ranging between 5-20°F immediately following the release of compressed air from the compression unit.

How Aftercoolers Function

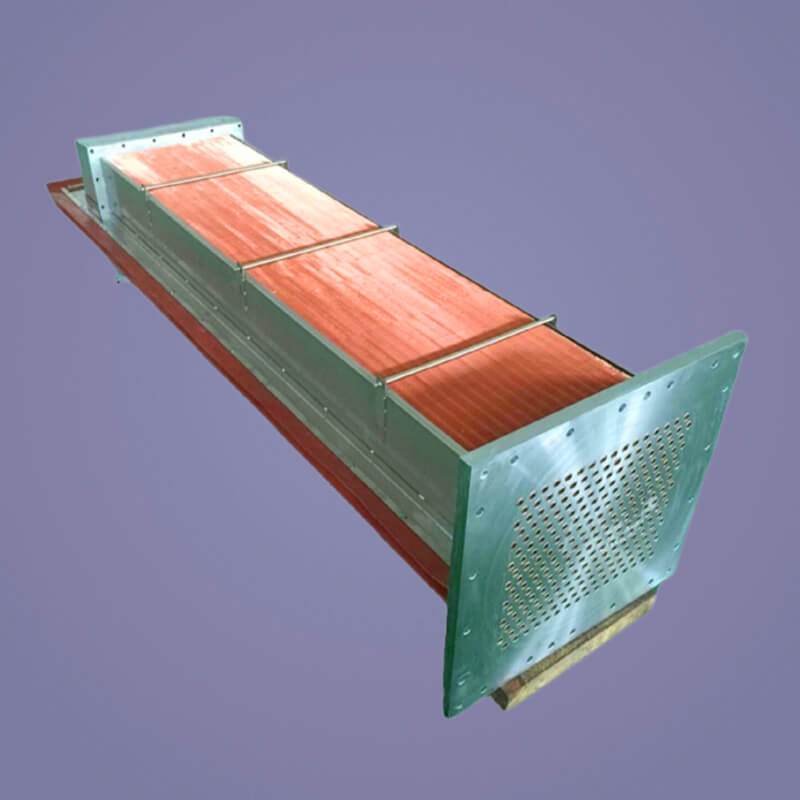

A standard aftercooler unit consists of tubing, often containing water or air, and fins that facilitate cooling. During operation, ambient air is drawn into the aftercooler, aiding in the removal of moisture from the compressed air through condensation. Simultaneously, process temperatures are reduced to acceptable levels. These aftercoolers are available in both water and air-cooled variants.

For air-cooled aftercoolers, ambient air is directed over tubes containing hot compressed air, facilitating a heat exchange process that dissipates the generated heat. Conversely, in water-cooled versions, water flows through tubes adjacent to compressed air pipes, achieving the desired cooling effect.

Distinguishing Features

While aftercoolers and intercoolers may appear similar and serve analogous functions, the context in which they are utilized underscores subtle disparities. An aftercooler primarily focuses on cooling the air emerging from a compression unit, whereas an intercooler is integrated into an air compressor to cool the air before its intake by the engine.

Benefits of Compressed Air Coolers

Both intercoolers and aftercoolers operate on the principle of cooling compressed air by expelling the heat generated during compression. This cooling process results in the condensation of water vapor suspended within the air, which can then be collected. The elimination of moisture safeguards moisture-sensitive components and prevents equipment damage stemming from corrosion facilitated by moisture.

Choosing the Right Cooler for Your Application

In summary, while aftercoolers and intercoolers share similarities and are often interchangeable, the specific requirements of your application should dictate your choice. For applications where cooled intake air holds paramount importance to engine function, opting for an intercooler is advisable.